Project basics

Due to the depletion of natural resources as well as the increasing requirements for all kinds of materials, more and more advanced technologies are being introduced into everyday life. Materials are no longer required only for durability, but also for more advanced features. Buildings currently under construction are not only supposed to be durable and beautiful, but they should also clean themselves, or clean the atmosphere in which they are located, so that people function in a safe and healthy environment.

One of the processes that can be used to make it possible to obtain the ability to purify air by buildings is photocatalysis. This is a process discovered a few years ago and described by Fujishima and Honda in the journal Nature. For the photocatalysis process to take place, light and a photocatalyst are needed. Light excites the photocatalyst and on its surface “electro-hole” pairs are generated, which are oxidation and reduction centers. As a result of a series of reactions, hydroxyl radicals are formed that are able to decompose organic compounds into carbon dioxide and water. The most popular photocatalyst is TiO2, a popular white pigment. The largest producer of this pigment in Poland is Grupa Azoty Zakłady Chemiczne Police S.A. The photoactivity of materials is obtained by introducing photocatalysts into the matrix of such a material. Increasingly, photoactive cement is used, the advantage of which is the ability to self-clean as well as air purification, but the disadvantage is its price, conditioned by the cost of obtaining the photocatalyst. Therefore, photoactive cements are about seven times more expensive than pure cement. The aim of the project is to propose a method of obtaining photoactive cements, which is to consist in modifying the existing cement production technologies so that there is no need to create separate installations for the production of photocatalysts.

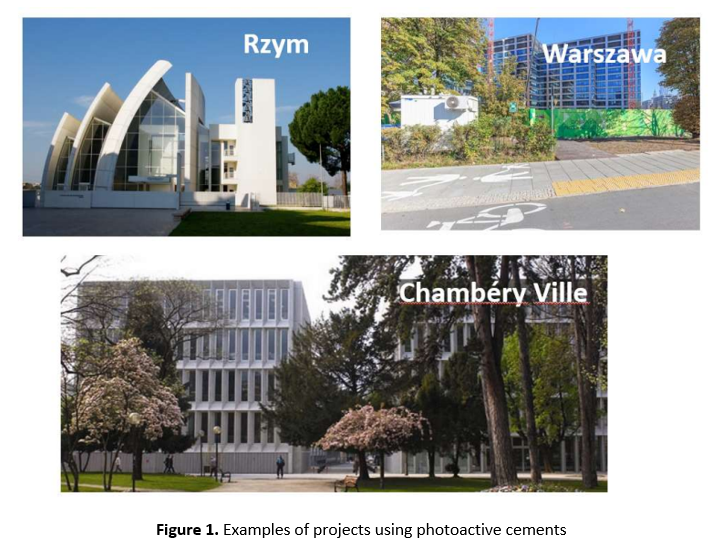

In recent years, the building materials industry has become very interested in the photocatalysis process. Photocatalysts are added to cements, gypsum, glass and ceramics are modified with them. Figure 1 shows examples of projects using photoactive cements.

Photoactive cements are up to 7 times more expensive than unmodified cements. This is due to the fact that the photocatalysts themselves are expensive, which in industrial conditions are obtained by two methods: sulphate and chloride, and in both technologies high temperatures are required to obtain titanium dioxide with the appropriate crystallographic structure. The photocatalysts are added to cements at the final stage of production together with other additives and admixtures.

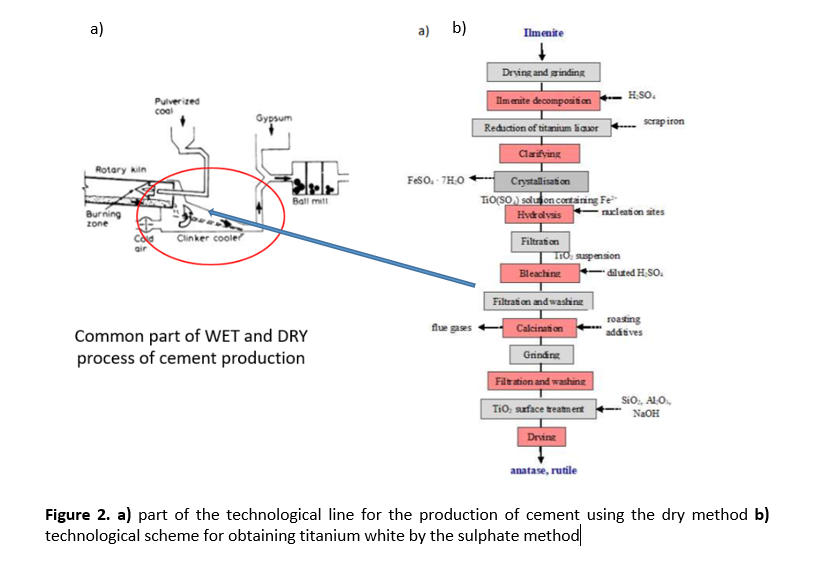

The novelty of this project is the use of the potential of the cement production line and the titanium white production line. In the technology of obtaining cement using the dry and wet method, raw materials are fed to a rotary kiln where they are calcined, and the temperature reaches up to 1450°C. After calcination, the clinker is cooled in a cooler in which it is cooled to a temperature of about 100°C and then ground with various additives and admixtures. The technology of obtaining titanium white is much more complicated and consists of many stages, but also in this process there is a calcination process, where the temperature in rotary kilns reaches 1300°C. In Poland, titanium white is obtained by the sulphate method in Grupa Azoty Zakłady Chemiczne Police S.A., the obtained material has a rutile crystallographic structure and is additionally coated with metal oxides in order to eliminate any photocatalytic activity because it is added to many materials as a white pigment and its reactivity is highly inadvisable. In order for the production of photoactive anatase to be possible, the calcination temperature should be lowered and roasting additives should be avoided. Even if someone would like to add anatase obtained in this way to cement, this method of obtaining cements is already patented.

Figure 2a) shows a fragment of the cement production process line – cooler, and Figure 2b) shows the technological scheme for obtaining titanium white. The key to creating a new, cheaper technology for the production of cement is to use the temperature in the cooler to obtain modified clinker by introducing into the cooler a semi-finished product from the technology of obtaining titanium white using the sulphate method taken from the technological line before the stage of introducing roasting additives and before calcination. The place of collecting the semi-finished product from the technological line for obtaining titanium white and entering it into the cooler is shown in Figure 2 with a blue arrow. This method is covered by the PCT application no. PCT/PL2020/050016.

←Tu należy umieścić zdjęcie.

←Tu należy umieścić zdjęcie.